Not all plastic is created equal…and neither is recycled plastic. It’s important not to think of “plastic” as a single entity, as the term encompasses a wide range of materials, each with very different properties and uses.

75% of the plastic that pollutes the oceans first comes from land, then enters waterways and is eventually deposited in the oceans. While some of this pollution comes from intentional littering, much of it is caused by improper disposal of post-consumer waste. According to UNESCO, approximately 100,000 marine mammals and 1 million seabirds are killed each year by plastic that ends up in the ocean.

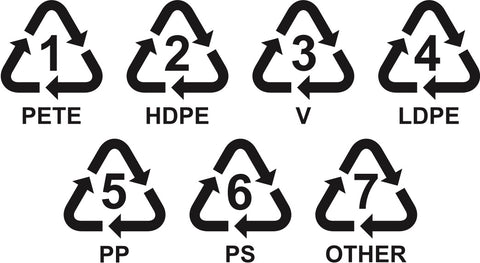

Faced with these environmental consequences, it is crucial to work to divert plastics from the waste stream into recycling and to clarify what can be easily recycled together. To make this easier, the Society of the Plastics Industry (SPI) introduced a resin coding system in 1988 at the request of recyclers. These codes are used to separate plastics into groups that can be recycled together.

At Marine Engineering, we don’t play favorites…any plastic that can be recycled, diverted from the waste stream or our natural environment deserves our attention. But the products that are most commonly recycled, and those that pose the greatest threats to our oceans, beaches and waterways, are the ones we are most worried about.

PETE (recycling code 1)

PETE (or PET), short for polyethylene terephthalate, was first synthesized in the 1940s by scientists at DuPont Chemical Company. Since then, it has become an extremely common plastic used in soda bottles, water bottles, and other types of food packaging. Its transparency makes it a lightweight, durable alternative to glass, where it is very popular.

PET is very easy to recycle and is often reused to produce bottles or polyester fiber. According to PETRA, the PET Resin Association, about 31% of PET is recycled in the United States, while Europe’s recycling rate is even stronger at 52%. It is easily recycled and is currently the most recycled plastic in the world, but existing recycling processes are still unable to meet the demand for recycled PET.

High density polyethylene (recycling code 2)

HDPE is the abbreviation of high density polyethylene. This plastic is most commonly used in packaging; including but not limited to milk bottles, laundry detergent, hair care products, and cleaning supplies. It is stronger than many other plastics and more resistant to physical and chemical damage. Therefore, it can withstand extreme temperatures and contain a variety of chemical agents without fear of degradation.

When recycled, HDPE is often reused in non-food containers and crates. High-density polyethylene’s light weight, strength, and ability to resist moisture make it ideal for products that must travel long distances to reach consumers. High-density polyethylene helps ensure these products arrive in good shape and with low shipping costs.

HDPE is 100% recyclable and is typically produced through a process of crushing, melting and subsequent pelletizing. Therefore, HDPE has a recycling rate second only to PET and is accepted by most recycling centers around the world.

PVC or V (recycling code 3)

The code used for polyvinyl chloride is PVC or simply V. PVC is a tough, strong and versatile plastic that can be rigid or elastic and available in clear, white and colored versions.

Due to PVC’s strength and durability in all weather conditions, it is often used in construction materials such as pipes, fittings, siding and hoses. It is also suitable for bottles of cleaning and personal care products due to its durability and lack of interaction with chemicals commonly found in these products. PVC is also used in medical equipment, food packaging and electrical conduits.

Its manufacturing process releases dangerous chemicals, and the chlorine in PVC is also released when incinerated, producing dioxins, a serious environmental pollutant. This makes it doubly important to properly handle PVC waste and divert it into the recycling stream to avoid additional environmental pollution.

Unfortunately, PVC is not typically recycled. When it finds a second life, it is often used in similar applications to the native variety, such as pipes, fittings and paneling. Recently, many synthetic wood and patio companies have introduced patio building materials made from recycled PVC. Other uses for recycled PVC include automotive applications such as fenders and floor mats, drainage and other types of mats, speed bumps and shoes.

If you want to know more about plastic recycling, please read the next information news.

Post time: 05-17-2024